How to Improve Your Fleet's Operational Efficiency

30 August 2022

To be efficient means being productive with little or no effort. Being efficient applies to many different situations, including a busy police fleet. If a fleet operation reduces costs while increasing fleet availability, it is operationally efficient.

Importance of Operational Efficiency

Steps to Improve Operational Efficiency

-

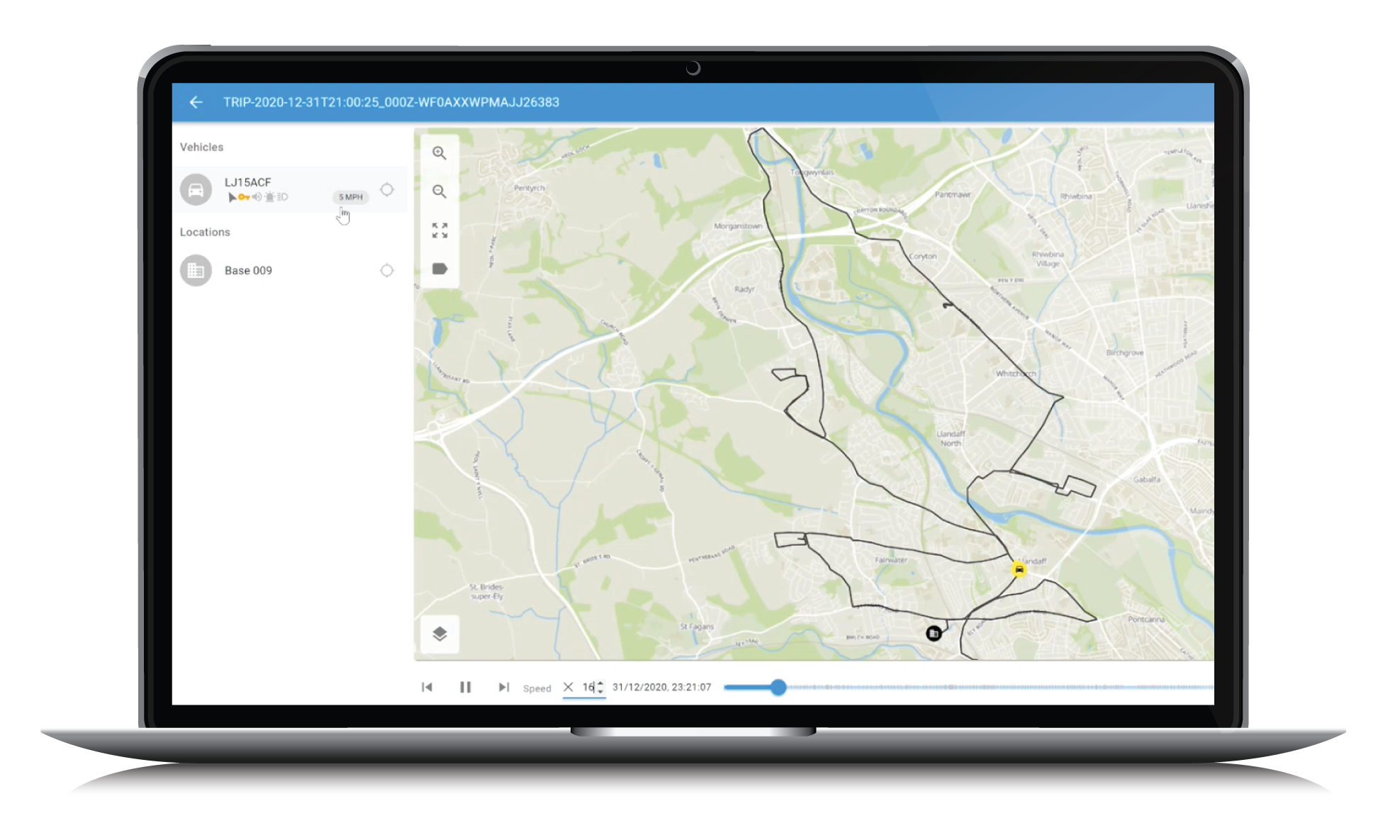

Our analysis shows that looking at usage in terms of time, number of trips and mileage gives a greater understanding of how vehicles in roles and locations are used operationally. It can highlight under and indeed over-utilised vehicles and offer police fleet managers with an opportunity to re-distribute vehicles within role or location to improve overall utilisation without operational impact.

3. Right vehicle at the right location and the right time

Experience shows that police operational managers value having the right vehicle resources available to them when they need them. Analysing vehicle downtime and the causes of downtime are essential in ensuring that vehicle availability meets the operational needs and priorities.

A good fleet management system used effectively will provide the fleet manager with a valuable insight into when vehicles are most likely to be unavailable and how quickly the vehicles can be put back online and ready for operational use.

This analysis can be complemented by a combined analysis of usage and downtime which can show when vehicles are most utilised during the day, specific days in a month or if key usage is cyclical or seasonal. Having this analysis can help fleet managers in planning scheduled maintenance to ensure that workshop downtime is kept to a minimum and ensure that, where possible, the downtime aligns to operational low periods where vehicle requirements may not be high.

4. Break Down Silos – Sharing vehicles

Many fleet managers have improved overall fleet availability and produced fleet savings by analysing and rationalising their fleets. A simple way to achieve this is by reducing vehicle roles to a minimum such that vehicles may have a multi-role or by rationalising roles where a vehicle is used in a general capacity.

Having a general-purpose fleet, especially at locations where several departments or operational units co-exist, can help improve overall vehicle utilisation, especially with pool-type vehicles. It can also ensure that underutilised vehicles are readily identified and realise fleet savings.

Having a readily available general-purpose fleet which is fit for purpose and suitably equipped can also reduce the need for daily rental and grey fleet usage which have other potential health and safety and road risk issues.

-

Experience has shown that police fleets which have achieved more inter-departmental sharing can reduce fleet costs by over 20% whilst improving the overall vehicle availability.

5. Improve Driver Behaviour

Improving driver behaviour not only improves core business aspects such as corporate reputation and risks but can also reduce costs such as fuel usage and general vehicle wear and tear.

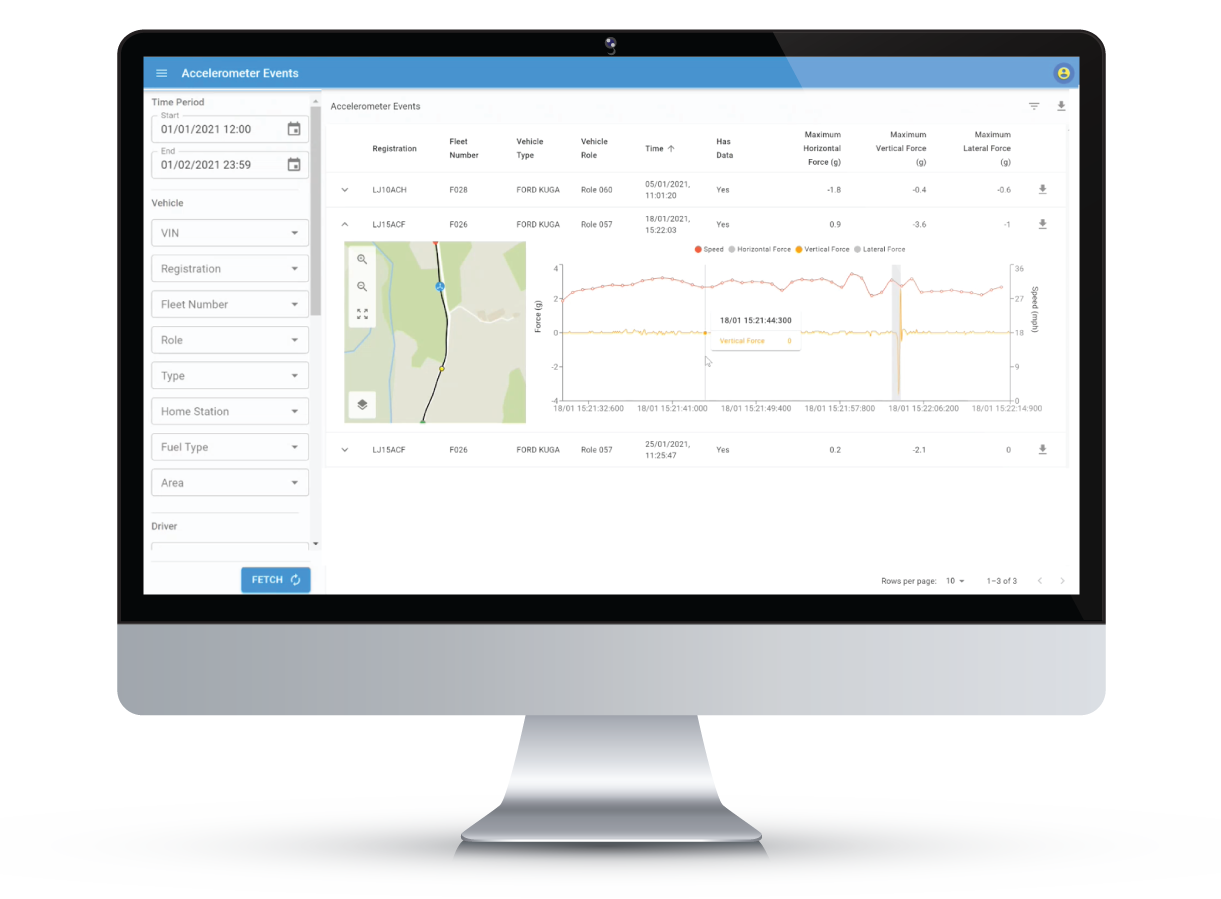

By analysing driving styles and assessing key elements such as harsh braking, cornering, accelerating and speeding, it is possible to compare drivers with their peers and so set targets as to “what good looks like” in terms of driving in specific modes such as response and non-response.

Early indications suggest that drivers are responsive to “league tables” especially when they see they are being compared with their peers. One initial project with a police fleet shows an 18% improvement in driver scores in only 90 days.

Some driving schools are using the driver score tables to help them assess which drivers may need refresher training and highlight examples of good driving styles which has helped reduce overall driver training costs as well as promote good driving.

A spin-off from driver behaviour monitoring has also been a reduction in motor insurance premiums as the fleet manager can show that they have effective driver monitoring programmes in place which in turn can show a reduction in collisions and the severity of collisions.

Integrate with other systems

The advent of “Big Data” within operational fleets can seem overwhelming, with a mass of data available especially when combining fleet management systems and telematics data. We have found that a simple but effective way to use this data is to combine fault codes and warning light data with fleet service, maintenance, and repair [SMR] data to help predict when a component may fail and how often such components fail.

By analysing telematics fault codes and SMR data, it is possible to forecast when key components may need changing ahead of their actual failure and therefore not only reduce overall SMR costs as a major failure often leads to further consequential costs, but also reduce overall downtime.

-

One fleet that saved over £24,000 in under three months by having early alerts on potential faults and being proactive in bringing in the vehicle for inspection.

- Improve fleet costs – fleet optimisation can highlight where fleet allocation improvements can be made and potential savings without compromising operational fleet availability

- Improve Officer / User Satisfaction – Ensuring vehicles are available when they are needed, not only reduces overall vehicle downtime and vehicle replacement costs but shows that the fleet department is working with operational departments to make the right vehicles available at the right time

- Drive Cost efficiency – Improving vehicle utilisation, reducing additional costs by monitoring driver behaviour, and ensuring greater vehicle availability by sharing resources will help drive cost efficiencies without the need for significant cuts in the operational fleet availability.

- Discover New Opportunities – Linking data from several fleet sources can help to predict when key components may fail or need replacing before the event occurs. A subtle revision of a vehicle’s servicing regime could save time and money so improving the overall availability of the fleet whilst reducing costs.

Want more information?

Get in touch today to find out how you can improve your operational efficiency

Contact Us