Telematics help fleets optimise their operations without comprising on core operations, safety, or cost.

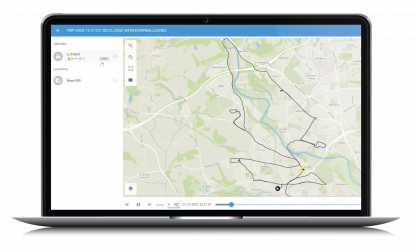

Lightbulb Analytics telematics solution is a fleet and resource management system which enables users to optimise their fleet and resources. Telematics goes far beyond just live tracking and vehicle status. Fleet managers can easily undertake fleet optimisation analysis, vehicle and personnel utilization, trip replays, assess driver behaviour, and potential collision analysis.

Seamlessly integrate with your other key business systems, allowing you and your team to conduct analyses on core operational activities. Multiple systems data can be captured and analysed within one core platform, integrating with fleet management systems, crime and intelligence software, ControlWorks, SAP, Capita TRSI and more.

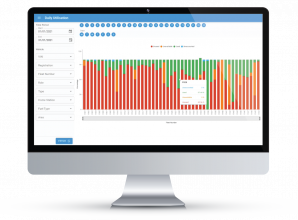

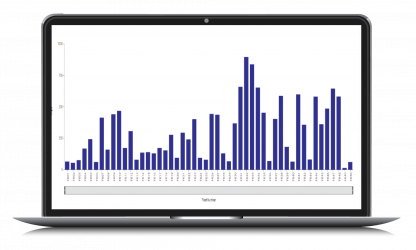

Optimise your fleet by analysing vehicle usage over time and pinpoint where vehicles may be over or under-utilised. Software can assist in reviewing the fleet with confidence levels to work out which vehicles are required, and a right fit for their intended role. It’s never been easier to maximise your operations.

Controllers, Supervisors and Managers have access to real time analysis of what resources (vehicles and people) are available, their current operational status and location. The software can also provide historic analysis of incidents, operations and patrols enabling managers to review the effectiveness of how resources were managed.

Our driver behaviour modules assess driving style and provides a score for each trip. The driver scores are analysed within the module and provide each driver and the fleet manager with an assessment of their driving. You can even use league tables for an engaging strategy to improve individual and overall driver scores over time.

Reach out to our team of experts for more information.

For the Kent and Essex Police, the mission is simple: to make the counties a safe place for people to live, work, and visit. To achieve this mission, they needed a data platform to improving efficiencies. Kent and Essex police installed Lightbulb Analytics fleet and resource management system in 2018. This software has quickly become key to driving efficiencies across both forces: in recycling assets, community engagement, officer productivity, reduction in operating costs and streamlining of working practices.

Please fill out the form for more information or to schedule a demo.

We take security seriously and will never share your email address with third parties.

Home » Products | Telematics systems

Copyright 2024 Lightbulb Analytics Ltd. | All Rights Reserved.

Company number: 01843754

Registered office address: Egale 1 80 St Albans Road, Watford, Hertfordshire, United Kingdom, WD17 1DL